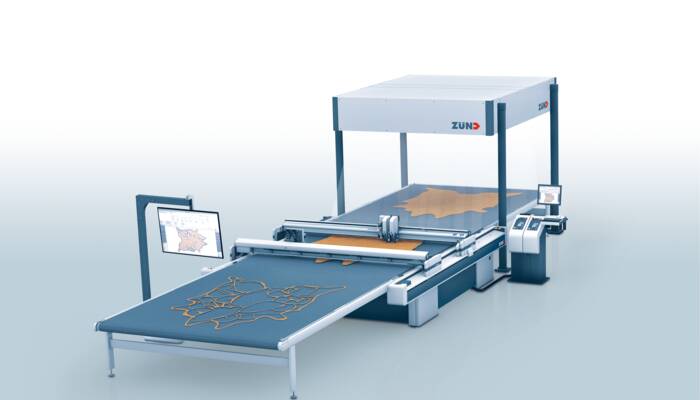

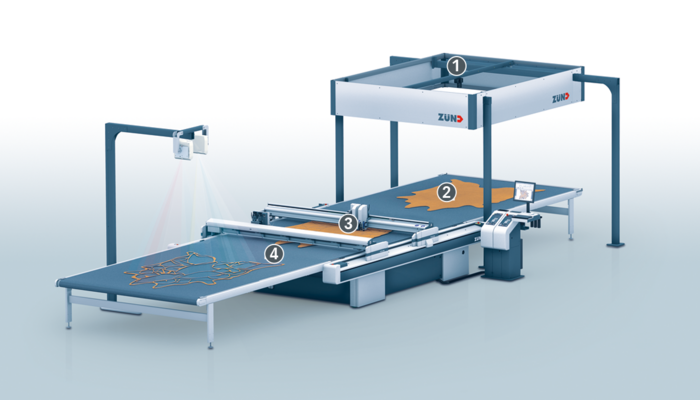

Digital cutting workflow

- Capture

A camera system captures the hide contour. The previously marked quality zones and flaws in the leather are registered automatically. - Nesting

The required cut parts are optimally placed to achieve the best yield possible. If desirable, the layout of the parts can be visualized via projection directly onto the hide. - Digital cutting

After nesting the parts, the system proceeds to cutting and punching with Zünd high-performance tools. A powerful vacuum system provides reliable material hold-down on the cutting surface. - Picking/sorting

For efficient parts removal, cut pieces need to be identified quickly and unmistakably. For this purpose, the parts are projected in color either on the hide or displayed on the monitor.

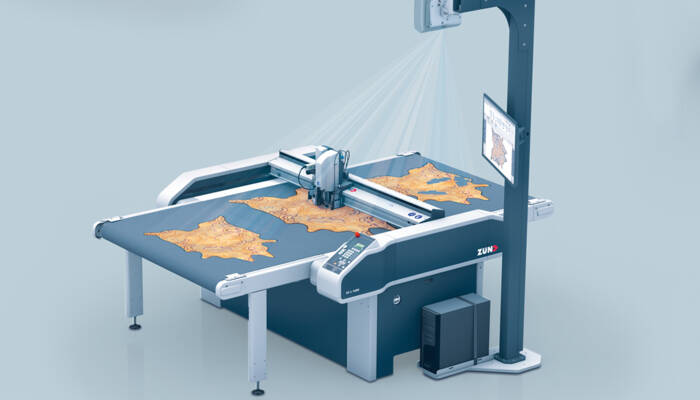

Small leather processing

Shoe production & accessories

The S3 and L3 cutter series are ideal for use in small leather applications. In this setup, the parts are typically projected directly onto the material and laid out manually. A camera for capturing the hide contour is available as upgrade. To reliably distinguish similar small parts from each other, the projection system can also be used for parts identification, which makes for easier picking/sorting.

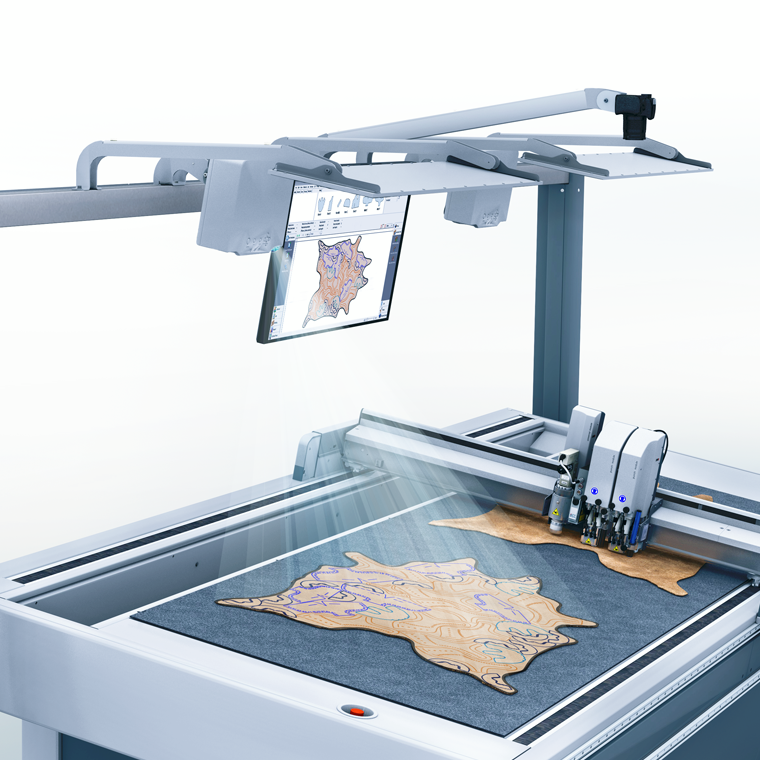

Large leather processing

Upholstery & Transportation

The G3 and D3 are the preferred cutter series for processing full hides. The camera captures both the hide and previously marked quality zones. Based on this data, the system then proceeds with automatically nesting the parts on the hide.