Craftsmanship + technology = innovation

Craftsmanship and digital, high-tech production do not have to be mutually exclusive; on the con-trary, at CoverWorks, innovation is what happens when the two come together.

Based in the Netherlands, the company specializes in upholstery and high-end textile and leather products. It relies on digital processes throughout its operations. Digital cutting automation with two Zünd G3 XL-3200 cutting systems plays a key role in this. Zünd technology unlocks new creative possibilities, shortens lead times, and improves material utilization.

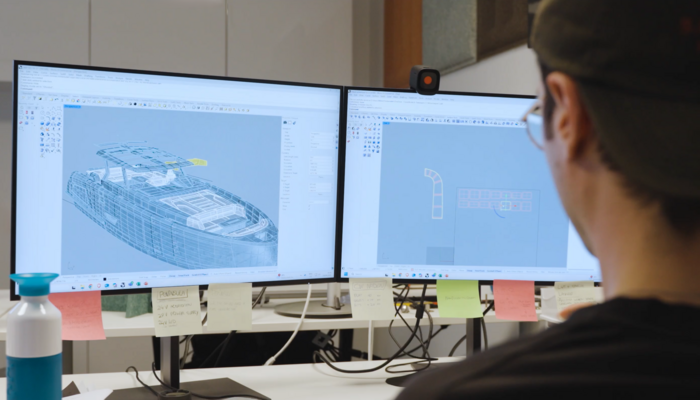

“The challenge in our work is the craft-based nature of what we do,” explains co-founder Gerhard van Geest. At the same time, the use of digital technology in design, product development, as well as in cutting and sewing, has become indispensable. “We had reached our capacity limits with the personnel resources available to us. With digital cutting, we were able to reduce lead times and can now take on considerably more complex work. It means we can design products with complex contours on the computer and then cut them digitally.”

CoverWorks relies on Zünd digital cutting technology and operates two Zünd G3 XL-3200 cutting systems. The two Zünd G3's are integral to their development and production process, emphasizes van Geest: “The Zünd cutting systems shorten our production and delivery times, and open up new possibilities in prototype development.” Beyond their efficiency and process flexibility, their sustainable design is also of central importance. It starts with reducing plastic waste through reusable packaging and extends to minimizing material waste through the use of Zünd cutting technology. By maximizing material utilization, digital technology enables efficient use of resources with minimal waste.

“Precision, quality, and service - those were the three most important criteria for us, and that's where Zünd really stood out,” says van Geest. While they had considered other solutions, ultimately Zünd emerged as the best option. “Many providers don’t have local service organizations, which inevitably leads to service delays. But when a machine is down, every second counts. If the machine stops, our company stops, and that simply can’t happen. Zünd is quick to be on site when issues come up, which keeps downtime to a minimum. That was one of the main reasons we chose Zünd.”

Parallels to competitive sailing

CoverWorks has been run jointly by Jeroen van Leeuwen and Gerhard van Geest since 2010. The two regatta sailors first crossed paths on the water, where they went on to win several world championship titles before joining forces to establish CoverWorks in 2004. From its beginnings as a small workshop producing boat covers and sprayhoods, the company has grown into a global player with production and customer-support hubs in Europe and Asia.

CoverWorks operates two production facilities in the Netherlands near The Hague, in Warmond and in Katwijk aan Zee. At both locations, production is fully digital, and both operate Zünd G3-series cutting systems.

Today, CoverWorks delivers its high-end products for a variety of applications to customers around the world. “We develop and produce a wide range of textile products and seating solutions, serving customers in the luxury market, healthcare, and other industries. We produce custom wheelchair seat covers, luxury cinema seating for superyachts, bicycle saddles, fabric coverings – and the list could go on.”

Ambition and innovation are the wind in CoverWorks' sails. With a flat, open organizational culture, van Leeuwen and van Geest are committed to continuous optimization and ongoing development – a mindset they brought with them from competitive sailing. “Behind every CoverWorks product is a highly dedicated team of more than 65 specialists: designers, upholsterers, engineers, and project managers. Modern production technology is important, but it can’t replace the intelligence of skilled hands. It can, however, complement them in meaningful ways.”