At the forefront of cutting automation in composites – Zünd at JEC World 2026

At JEC World 2026, Zünd is presenting a fully integrated, end-to-end solution for automated cutting in composites manufacturing. Zünd is an independent, global, family-owned Swiss company known for premium digital cutting systems that integrate hardware, software, and supporting functions into a cohesive, automated workflow – from file preparation to digital cutting to parts logistics.

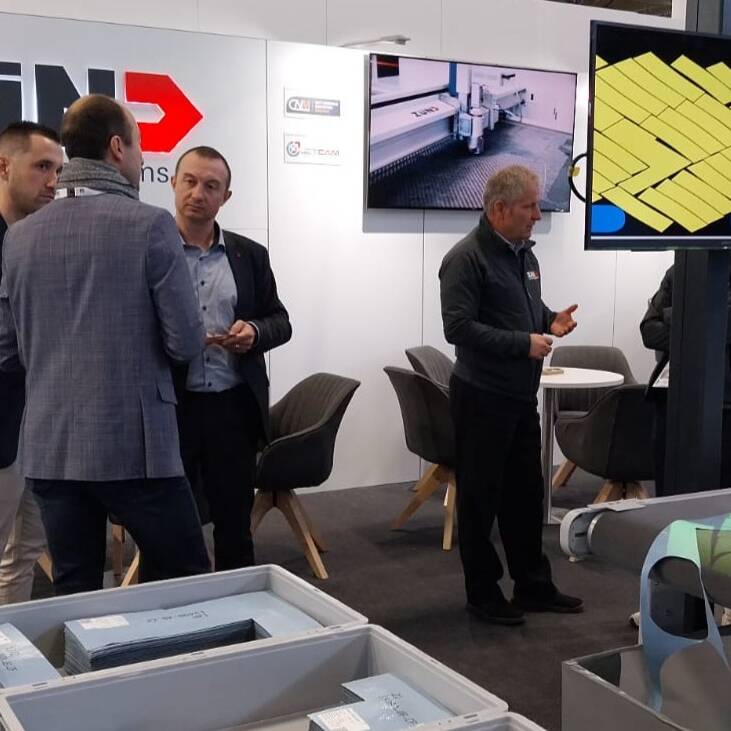

JEC World takes place in Paris from March 10–12, 2026. At booth S57 in Hall 5, Zünd demonstrates how integrating cutting data and material handling improves composite-cutting performance. Software-supported workflow automation creates a production environment that delivers reproducible quality, high process reliability, and shorter lead times.

From job data to kitted parts: digital production cell live at the booth

The centerpiece of the Zünd exhibit is a fully integrated production cell that demonstrates how composite-part manufacturing can be digitized, automated, and scaled to an industrial level. The demonstration focuses on measurable improvements throughout the value chain: optimized use of materials, reduced waste and lower quality-related costs, fewer manual steps, and more structured parts handling – all in one highly user-friendly system.

The production cell consists of a Zünd G3 cutter, a ProWinder Vision from material-handling partner CNM, and software solutions from Zünd and its software partner Jetcam. It illustrates how an end-to-end digital workflow makes cutting prepreg and other composites more efficient.

Zünd is also presenting a new optional belt-cleaning feature that keeps the conveyor belt clean by reliably removing loose fibers, lint, and other residues. In addition, a new labeling module is used to mark cut parts. It enables tracking parts and provides unique part identification for downstream logistics while also supporting the kitting process (sorting, grouping, sequencing).

The Zünd PreCut Center ZPC plays a key role: In addition to automatically nesting contours – while taking irregular material shape and defects into account – the software enables job data to be included in the output file. The data is then applied directly to the cut parts using inkjet or a label printer. This metadata provides the basis for kitting, ensures full traceability, and enables efficient and more reliable downstream processing.

To facilitate removal, the system uses an intuitive marking and projection system that visually guides the operator in picking and sorting cut parts. This enables standardized processes and shorter training time – key factors in achieving consistent quality in a challenging production environment.

Zünd also presents the ZCC Zünd Cut Center operating software: Touch-optimized, modular for easy expansion, and equipped with flexible automation options, ZCC supports job preparation and cutting tailored to the specific requirements of the composites industry.

Premium performance with predictable profitability

Composites applications require precision, repeatability, and process reliability, but equally important are productivity and system availability. Zünd addresses these challenges through modular cutting systems, intuitive operation, and a fully integrated software ecosystem. The combination of high performance, low downtime, and efficient use of materials ensures that investments in a Zünd cutting system deliver real economic value throughout its entire life cycle – without compromising quality or ease of use.

Another major benefit – Zünd support services: From application consulting and process analysis to training, a global service organization, and prompt spare-parts availability, Zünd helps customers get automated production workflows up and running quickly and keep them running reliably over the long term. The result is reliable, scalable production – with predictable operating costs and strong investment security.

Robust industry partnerships

In composites manufacturing, Zünd works closely with specialized, experienced integrators to provide comprehensive end-to-end solutions – from the digital cutting process to highly automated assembly and parts logistics. These partnerships are built on proven process expertise and tightly integrated interfaces that connect machines, material-handling systems, and software.

A key highlight is Zünd's collaboration with Loop Technology (Hall 5, booth Q112). Loop Technology is presenting the FibreLINE high-speed preform system designed to enable automated cutting, ply sequencing, and layup of large plies for applications in aerospace, wind energy, and other industries. With the Q-Line and its dedicated machine-to-machine interface, Zünd cutting technology plays a central role in the automated production cell for cutting large structural parts up to 21.4 m (70 ft) in length. Multiple aerospace installations already in operation underscore the importance of high-precision, reliable, and efficient automated cutting for the future of this industry.

Zünd also maintains a long-standing sales partnership with Airborne Composites Automation (Hall 5, booth M71). Together, the companies provide automation solutions for processing composite materials with a focus on automated cutting, kitting, and preforming. Other partners such as CNM and Jetcam complement the portfolio with high-performance material-handling solutions and software-supported data workflows, enabling end-to-end automation in composites manufacturing. CNM presents its unwinder solution for prepreg and dry-fiber materials at the Zünd booth. The company is also demonstrating a camera-based inspection system for detecting material defects in prepreg and documenting them in a digital defect map.