Automation and AI – Zünd and its partners are redefining leather processing

Zünd is setting new standards in highly automated and integrated leather cutting, together with partners Mind and Mindhive Global. At Simac in Milan, the three technology partners will be unveiling the Dectura Workflow. Industry experts will experience firsthand how AI, machine vision, and digital cutting systems are working together perfectly to make hide capture, classification, and cutting even more precise, reliable, and faster than ever before – all within a fully networked environment.

When Simac Tanning Tech opens its doors in Milan on September 23, (almost) everything at Zünd’s booth A48/B47 in Hall 10 will revolve around the fully automated detection of defects in order to achieve perfect cutting results. Together with technology partners Mind and Mindhive Global, the Swiss specialist in digital cutting systems will showcase the Dectura Workflow, a completely integrated solution for precise and efficient leather cutting.

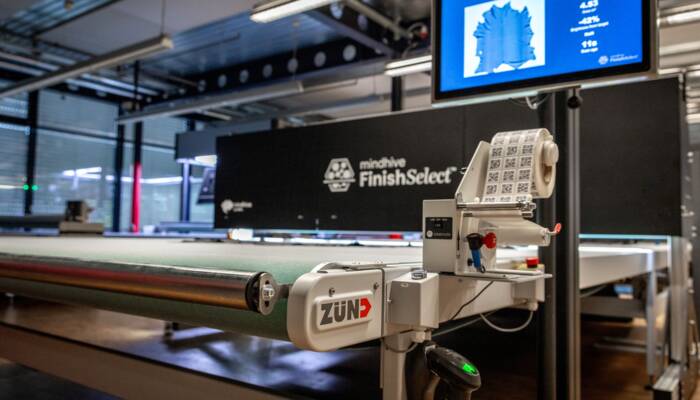

The leather-processing and production workflow encompasses Mindhive FinishSelect™, which uses AI support to capture, evaluate, and measure hides in seconds; MindCUT software from Portuguese software partner Mind; and digital cutting technology in the form of a Zünd cutter.

Automation in an increasingly digitalized leather cutting environment is no longer a vision of the distant future – it’s today’s reality. And it’s fundamentally transforming how leather hides are captured, evaluated, graded, and ultimately cut. In the Dectura Workflow, artificial intelligence has entered the picture and is taking the hide evaluation and grading process to an entirely new level. Hide evaluation and grading were previously an interpretive process that was largely manual, error-prone, and inconsistent.

With Dectura, innovative technology leaders Zünd, Mind, and Mindhive Global are showcasing a technological breakthrough that enables highly automated and standardized leather cutting using AI, image-based quality assurance, cutting-edge nesting and cutting software, as well as a powerful digital cutting system. Dectura empowers leather processors to make the leap to smart, data-driven processes that deliver consistently repeatable quality and digital integration.

The components

- Mindhive FinishSelect™ creates a high-resolution image of the hide, using machine vision and deep learning to detect more than ten different defects in mere seconds with an accuracy of up to 0.17 mm (0.0067”) and classifies hides according to user-defined criteria. The AI-powered solution grades the hides so precisely that up to 90% fewer parts are rejected in quality control prior to sewing.

- Transport table with labeler from Zünd

- MindCUT software The MindCUT operating software is the cutting-room control center. MindCUT is flexible, adaptable, and offers all the necessary components for digitalization, nesting, cutting, and parts removal.

- Zünd Cutter Zünd cutters are ideal for efficient digital cutting of hides in all different sizes. Zünd’s digital cutting workflow enables unmatched flexibility in leather cutting. Zünd cutters also set new benchmarks in terms of speed and efficiency.

The workflow

The entire process – from scanning the leather to cutting – is digital, efficient, and requires minimal manual intervention. Hide evaluation now takes just 15 seconds, saving companies up to ten minutes per unit, while simultaneously providing complete digital documentation for each individual hide. In addition to realizing significant time savings during the evaluation process, users also benefit from the comprehensive material documentation they can use for traceability, quality assurance, and production planning.

G3 Compact Cutter

With a compact G3 cutter, Zünd will showcase yet another master of leather-cutting efficiency in action. This limited-footprint cutting system meets the technical requirements specific to the leather industry. With a working area of 227 x 160 cm, the G3 compact cutter is ideal for processing medium-sized hides and offers sufficient space for nesting, cutting, and parts removal on one machine. For maximum user convenience, cutter operation, hide loading, and parts nesting are all handled centrally from the front of the cutter. The cutting workflow runs from front to back and is split into three areas: loading, cutting, and parts removal. This enables loading and capture of a new hide, or removing cut parts, all while cutting is in progress. It eliminates downtime and significantly boosts productivity.