When AI understands leather

How modern image processing, neural networks, and digital cutting are interacting with each other – and fundamentally changing leather processing.

For a long time, the grading of leather hides was a craft that, above all, required experience and intuition. These days, the use of artificial intelligence is fundamentally changing the way leather is graded.

No two leather hides are the same. Scars, scratches, warts, insect bites, wrinkles, or other impurities – each hide has its own peculiarities. Some are obvious, but many are only noticeable upon closer inspection. For production, this means each hide needs to be individually inspected, graded, and then cut accordingly. This is a time-consuming process that previously required a great deal of skill and experience.

It quickly reaches its limits, especially in leather processing industries such as furniture, automotive, fashion, and accessories, where high quality and reproducible results are indispensable. Manual inspection of hides is not only time-consuming, it is also prone to error. Furthermore, the process is also only partially standardized and therefore delivers inconsistent results, which is especially concerning when you are grading hundreds of hides a day. This is precisely where a groundbreaking new Dectura workflow comes in, which Zünd and its partners will be presenting to the public for the first time at SIMAC.

Neural networks at the core

Neural networks form the basis of the AI-supported grading solution. Inspired by the human brain, neural networks process image data in a way that conventional machine-vision or machine-learning technology could never do. Instead of rigid rules, neural networks use learned patterns to reliably detect even the smallest defects in the leather hide. This is the case even in difficult lighting conditions or with highly variable surfaces.

The network has been trained with tens of thousands of images and now detects more than 20 different types of defects in tanned leather hides. It works at the pixel level, which means even the smallest deviations of less than 0.17 mm are reliably detected. And it isn't affected by mood or fatigue. Unlike with human detection, the performance of the new AI solution remains consistent – around the clock. If the system detects a defect, other specialized system components calculate the affected area and determine the quality category.

The AI-supported system has been trained to detect more defects specific to different areas and types of leather than a human would ever be exposed to. And it applies this expertise consistently, without losing concentration or attention.

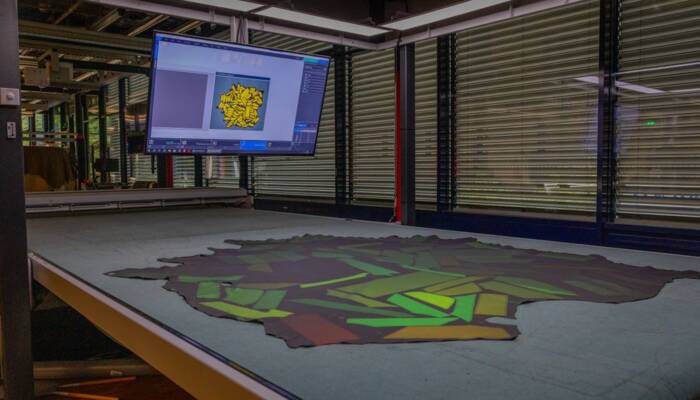

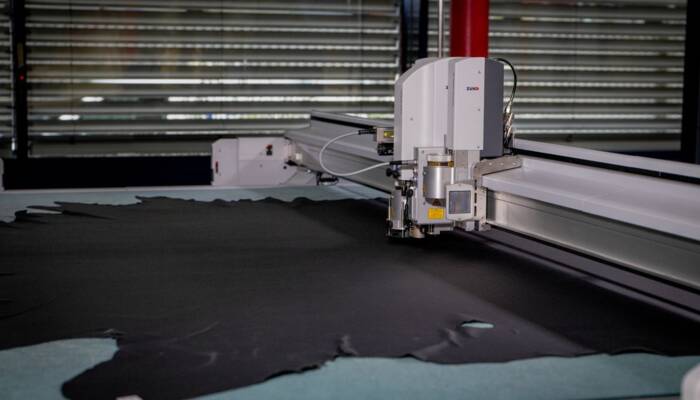

After detection, the affected zones are measured, the overall quality of the hide is graded, and the cut parts are positioned automatically. Each defect is taken into account as the parts to be cut are positioned in individual, user-specified quality zones. This ensures maximum utilization of the material. The final step is precise, fully automatic digital cutting.

Precision meets standardization

What makes the new solution unique is its consistency. While human assessment may vary, the system consistently delivers the same quality – regardless of shift, location, or workload. This leads to standardized results in production and enables reliable downstream processing.

For anyone who works with leather – whether in the furniture industry or invehicle interiors or accessories – this technology offers real advantages. It makes processes leaner, results more reliable, and opens up new opportunities in production. In short, it changes how leather is graded and processed. Above all, AI ensures near-total elimination of waste. The AI-supported solution grades the hides so precisely that up to 90 percent fewer parts need to be rejected in quality control prior to sewing.