When quality and versatility matter most

Texas Nameplate, a 3rd generation, family-owned business, demonstrates the many ways investing in a Zünd pays off—from conquering challenges to future-proofing their business.

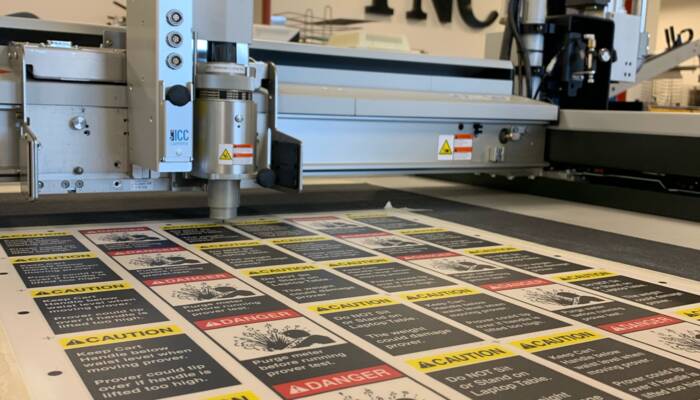

Founded in 1946, Texas Nameplate has been producing nameplates, tags, and custom labels for many different industries. The substrates and processing methods they use include a variety of metals and flexible materials, screenprinting, chemical etching, and of course, multi-functional digital cutting.

When they needed room to grow, they moved from their original location in Dallas to Lancaster, Texas. At their old facility, they were limited in space and were using an outdated cutting table that proved incapable of keeping up with higher demand. While Dan and Ryan Crownover, brothers and third-generation family owners, were travelling around the country, they stopped by a similar print shop that had an older Zünd cutter. It was still going strong, and the shop owner said it was the best piece of equipment they had in their facility. Rarely requiring any service over the 20 years they had owned it, the Zünd cutter was still performing with extraordinary versatility and dependability. This led Dan and Ryan to start thinking about owning a Zünd for themselves.

They did their research, including speaking to other Zünd owners, going to Zünd’s website to look at the different models and options available, and watching a lot of YouTube videos showcasing different cutting projects. Top priorities for Texas Nameplates’ cutting operations were versatility and adaptability—making sure the equipment would meet all of their production requirements—now and later. Once installed, the Zünd proved itself in other areas as well: dramatic increases in capacity, the ability to consistently meet tight deadlines, impeccable cut quality and precision, and, of course, dependability, along with prompt service and support in case anything happened to go wrong.

Another important consideration for the company continues to be sustainability and environmental stewardship. Because of the ability to maximize sheet size and material yield, the Zünd is delivering important savings in terms of material and print costs. Says Dan Crownover, President at Texas Nameplate: “If you’re going to get a piece of equipment, just go for the best! When you get the kind of equipment in that improves quality and lead times and simultaneously increases your versatility and ability to improve production processes, that helps you—and in turn, your customers—save money.”

Since installing their Zünd cutter, Texas Nameplate has been able to dramatically cut lead times. Jobs that might have taken a couple of weeks in the past can now be completed in 1-2 days. Prior to owning the Zünd cutting system, they had made the decision to move away from some of their sticker and decal business in order to concentrate more on higher-margin nameplate jobs. With a Zünd at their disposal, they were able to get back into those markets because they now have the room and the time to do it all.

One of Dan’s favorite things about the Zünd is how easy and affordable it is to upgrade, which makes it a machine that can grow and adapt to changing business needs. This means that if they decide to add a new product line, they don’t have to buy a whole new machine; they can simply add new tool and workflow options to their existing system. This, too, helps keeps their costs down and allows them to pass those savings on to their customers. To sum it up, the Texas Nameplate team loves working with their Zünd—it continues to ensure their business stays productive, competitive, and future proof.