ZCC Zünd Cut Center – What's New?

Listing of the most important new features of the latest Zünd Cut Center version.

ZCC 4.6.0

Essential new features in ZCC 4.6.0

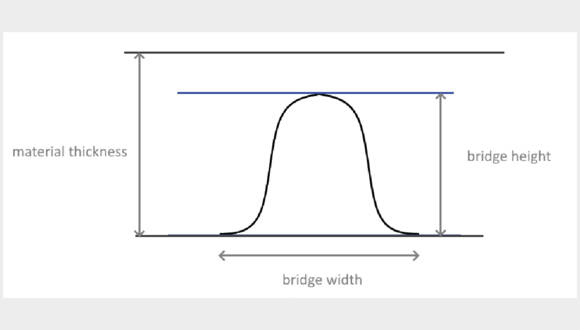

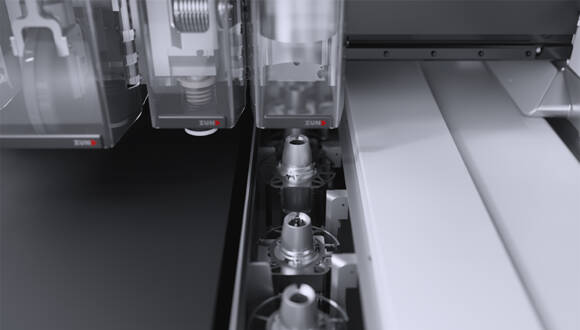

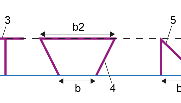

Cutting bridges can be time consuming. Previously, the tool would stop before the bridge, move up, and then move down again after a few millimeters to continue cutting. To save time and increase throughput, the process of cutting and routing bridges was improved. (only on Gen3 cutters)

Now, bridges are cut in one pass at a defined height.

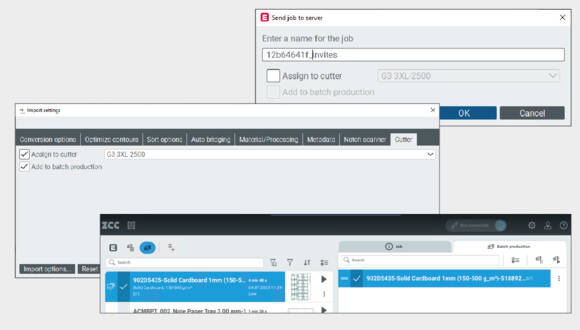

Can you add a job to a batch during import or when sending to the job list? Yes, this is now possible!

There are now different options for automatically adding jobs to running batches. If you have more than one cutter, you can assign a job to a cutter. Whether you import jobs to Cut Editor and send them or set the addition to a batch as part of the import settings data workflow, jobs are automatically added to the running queue and processed with the running batch.

Assigning a job to a specific cutter is also possible without adding it to a batch. Once assigned, the operator can view the assigned job list and produce the jobs one by one.

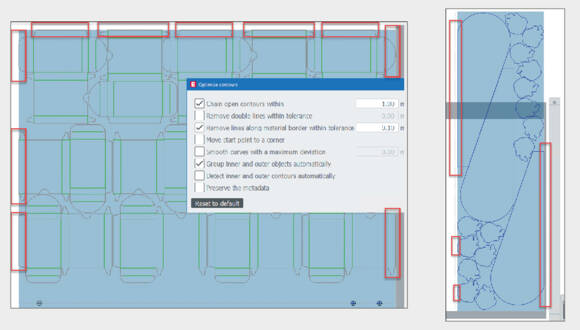

Removing the common lines from the edges of the material saves the user cutting time, but also material – because the nesting efficiency increases when parts are nested to the material border.

Previously, when cutting alongside a material edge risked damaging the knife or wrinkling the material. Additionally, it was an unnecessary cut that increased cutting time.

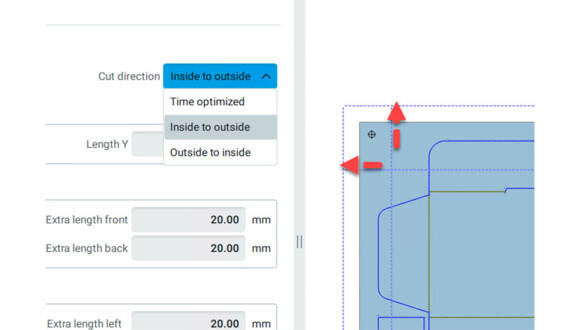

Cut Center now handles the cutting direction for lines intersecting the border. Cutting is done from the inside out, so that the material is not pushed away.

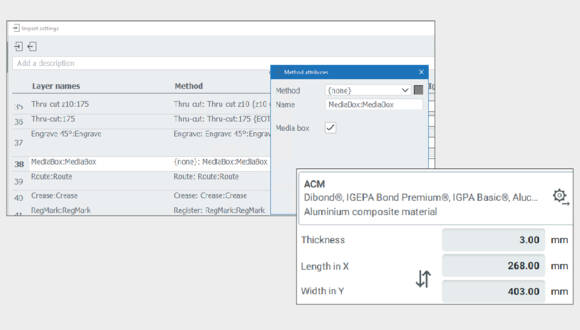

Material size is a frequently needed information in the production workflow. For example, it is necessary for automatically loading material and for correctly arranging the vacuum width. If this information is missing from a job file, it can be inserted manually. Importing files with a hot folder or the Cut Editor is supported by import settings that enable the addition of information to the job.

However, to save time and streamline the production workflow when the material size information is missing, the ability to extract the material size from the input file has now been added to this workflow. To do so, the media box is considered. This is a standard element of a PDF file. If the media box is not present, the designer can add a layer that will be converted to the material size.

Barcode Workflow

- Supports multiple job production, from roll or sheet material

- Manual entry and skipping of unrecognized codes

- Uses barcode position for position alignment (only if present in the job data)

Register Mark Detection

- Improved accuracy, even with material distortion

- Supports backup registration tool

- Skips copies if marks are not detected

ZCC 4.5

Essential new features in ZCC

A new "Cut Jobs" application is included in the Cut Center Advanced license.

At the core of Cut Jobs is a job list with a variety of functions like those of the one in Cut Center. A new function has been added for assigning jobs to individual cutters.

With any job, the user can now decide which cutter to use. This allows operators to filter the list so only jobs relevant to their particular machine can be seen.

The feature is meant to be installed on any computer, usually in the same location where jobs are prepared and managed.

- Install Cut Center wherever most suitable

- Import ZCC files

- Edit, replicate, or delete jobs

- Open files in Cut Editor (if installed on the same computer)

- Assign jobs to a specific cutter

Border Detection is useful for teaching the system the position and orientation of the material and aligning the cut contours accordingly.

ZCC Cut Center has been enhanced with an optional corner detection. This reduces registration time when working manually and avoids wrong detection of borders whenever multiple sheets are placed close to each other. Highly recommended to activate this optional solution!

Further, two detection algorithms are available to choose from. They may be used for both, Border Detection and Reading Register Marks.

The two choices of algorithms are:

- “Color-based”: Activated by default; best for uneven edges

- “Contour based”: Additionally detects lines; best used when the material and conveyor are similar in color

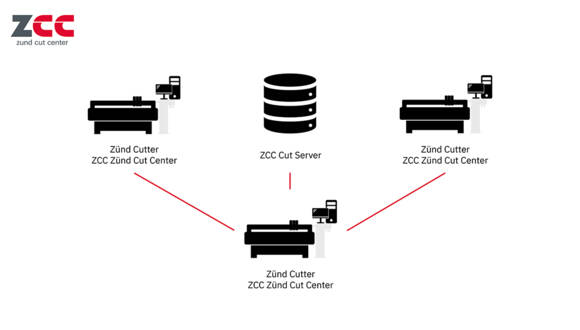

Normally, one Cut Server per location is sufficient. The Cut Server may be installed on a computer in the server room or even on a virtual computer, making it less accessible. It is now possible to manage hot-folder settings, set depth offsets for each cutter, and if necessary, restart the Cut Server from the PC where Cut Center is installed.

Depth offsets are saved for each individual cutter. This new support of individual offsets enables the use of depth settings per material on each machine; the system then adds a correction for best results on each cutter, no matter which one is being used.

This reduces costs since only one Cut Server is needed per customer. It facilitates installation and setup and also makes it easier for the customer to maintain the one material database.

The set-up for notifications from Microsoft Teams or e-mail has changed. ZCC now uses a different Microsoft API since the previous solution was discontinued.

Bevel Cut

With the smarter handling and set-up of bevel cuts, an improvement to the visualization made sense (in Cut Center and Cut Editor). The user can now control in the settings which side needs to be beveled, and the same can now be seen in the new and improved visualization—What You See Is What You Get.

For Bevel Cut, the base depth no longer affects the dimension of the shape/contour. The end product will be the correct size, no matter the depth setting.

Routing

For Routing, the visualization in Cut Editor has been improved as well.

The setup and usage of the AKI (Automated Knife Initialization) now works the same way as the ITI.

When using a cutting underlay, e.g. for routing jobs, it is no longer necessary to add in the underlay thickness. As with the ITI, ZCC now adds the underlay thickness automatically. Therefore, initialization now works the same way for both, the AKI and ITI – on the cutting underlay.

Starting with ZCC 4.5.0, the Cut Center material database contains revised parameter sets for the material groups Soft Boards, Self Adhesives, and Non-Adhesives, as well as new additions such as multi-layer corrugated and EE flute materials in the Soft Boards group.

When updating the software version, the standard parameters in the database will be replaced with the revised ones, while all user-defined parameters and user-defined materials in the database will remain unchanged.

ZCC 4.4

Essential new features in ZCC

In an automated production environment, the use of material loading systems such as sheet feeders, BHS or unwinders is critical to maintaining uninterrupted production. Especially during lights-out production shifts, when human intervention is not possible, the system must be running. A user-defined value for skipping sheets can be set in Cut Center so that production continues even if the QR code reading fails or the job is not in the database.

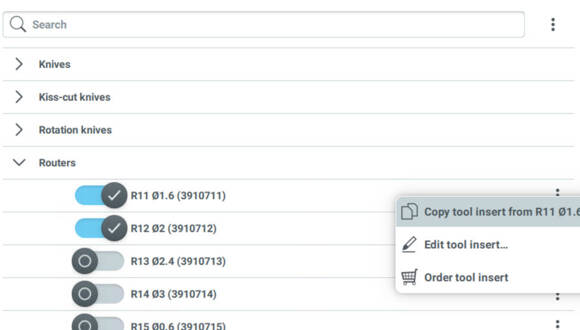

Order your consumables such as tool inserts in the most convenient way: Start the ordering process directly from the tool insert list in Cut Center, which makes it easy to find the right consumables immediately. Simply add the items from the tool insert list to your shopping cart in the MyZund webshop.

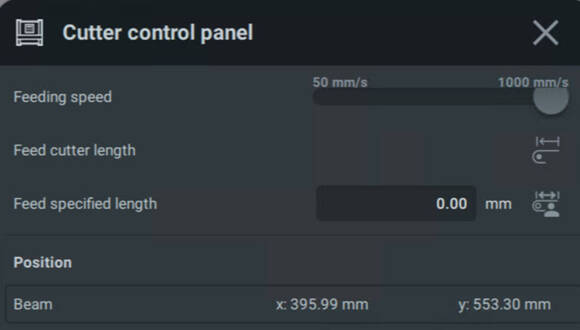

The Cutter Control Panel has been enhanced with new feeding options. Even more interactive movements are possible within the Production View.

When viewing the cutter preview, you can now interactively move the beam by pointing into the image. This can be helpful to quickly and easily check if the job will fit on the material, or to quickly move the beam to a position where a reference point should be placed.

Cutting the waste is important for a smooth waste removal. Some materials need to be cut from inside to outside, in order to avoid damage. With Cut Center now offering such an option, both the final product quality and the operator experience are improved significantly.

ZCC 4.3

Essential new features in ZCC

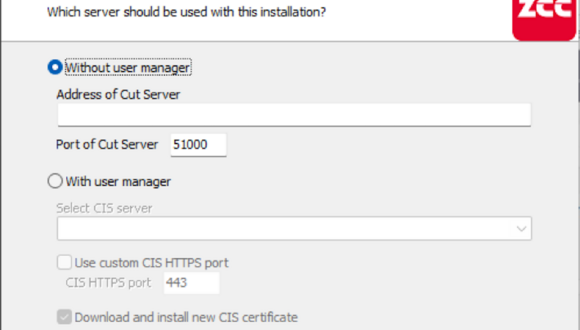

It is now possible to install ZCC with or without user management by the CIS.

Depending on the decision if user management is needed or not, the installation process is easier without user management, because no certificate and less open ports are needed for secure communication between CIS and ZCC.

In addition, the ports may be changed if the default ports are used by another application.

The respective documents have been updated:

- IT installation information (for IT department at customer)

- Installation manual (work in progress, expected publication date 13. May)

- PC requirements

- Landing pages with IT settings for Gen3 and for Q-Line

The option is applicable for Gen3 cutters only.

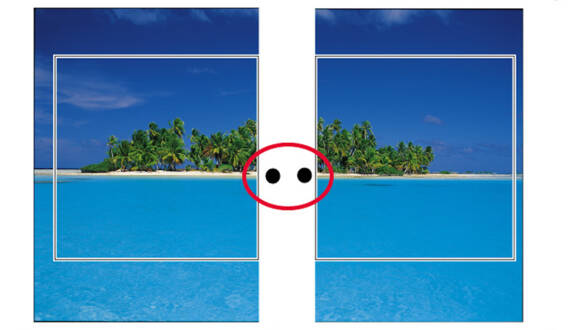

Align marks can be placed at a point of interest. Zünd Cut Center will then interpret the align marks and ensure the cut contours are aligned to this point.

It is now possible to combine the align marks with the registration type "Fit to Objects". This will ensure the point of interest is always on spot, despite a potential distortion of print.

ZCC 4.2

Essential new features in ZCC

We’ve upgraded the production process for your convenience! Just make sure you have a spare tool mounted on the cutter or available in the tool changer. The Cut Center will automatically change over to the spare tool once it identifies if a tool insert wears out or reaches maximum cutting distance.

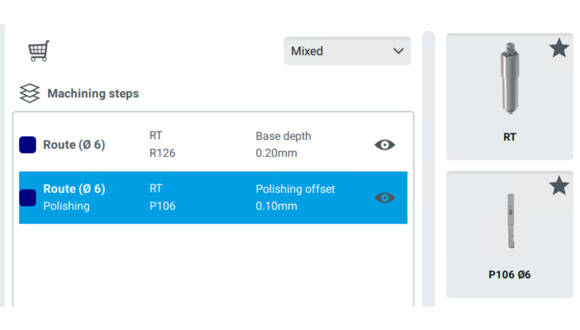

After the initial shaping, we've made it even easier for you! Now, with the polishing path seamlessly integrated into Cut Center, refining surfaces is a breeze. We've put you in control, letting you adjust settings just like you do with other machining steps. Enjoy a more efficient and user-friendly experience!

Experience enhanced productivity with the latest Cut Center 4.2 feature!

- Using two board-loading devices, while distance between the devices is perfectly optimized at a half-cutter width

- Reduced cycle times for BHS 180

- Pick & Place supports picking items with holes and has new settings for better-picking parts bigger than the end effector

- Visualizing Option optionally marks all parts of a set at once for smoother sorting

The Zünd Cut Center provides numerous ways to automate production and streamline workflows, boosting efficiency and production quality.

Pause Hotfolders

Hotfolders are a fantastic tool to simplify data import and enhance data by optimizing settings on import. Any file landing in such a hotfolder gets seamlessly imported to the job database, following specific import and optimization settings per folder.

For experimenting with different settings, a pause function for individual folders was implemented.

Processing

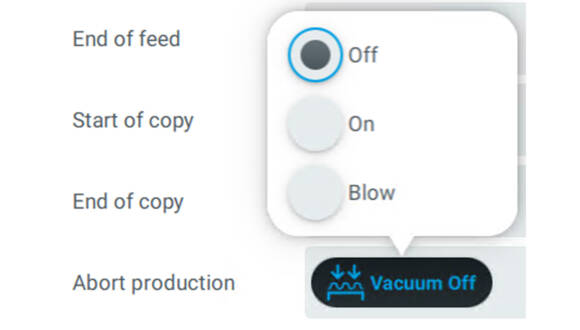

Processing steps ease the lives of operators and automate steps, reducing the need for manual intervention and saving valuable time. The new section “Abort Production” lets operators define automatic action on the abortion of a job.

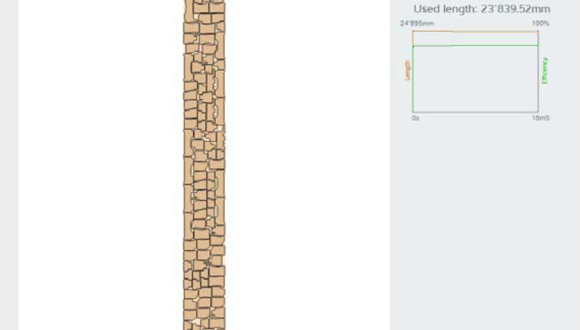

Understanding the production time per cutting job is crucial for effective production planning. Not only does the operator see in Cut Center Advanced the estimated time before and during production, but also in Cut Editor the time per job may be estimated, based on all cutters on the shop floor.

Also, external systems can query the cutting time estimates via the ZCC interface.

ZCC 4.1

Essential new features in ZCC

Benefit from tools assigned to the material: this means you can use the sharp knife for one material and the worn knife for another material. Instead of being assigned alias names as before, each tool insert can now be given a tag. With this tag, you can assign the tool insert to a material in the material database. There may be different tool inserts on the cutter or in the magazine, with each used for different materials.

Use different settings for one knife: you can assign different settings to .various methods while still using only one knife. This will make setup for cutting with one knife on different tool settings easier. Using tags allows this to be automated for jobs sent by third-party software via the ZCC interface.

ZCC 4 sorts the cutting sequence in an optimized manner and therefore reduces the empty run distance.

Some materials and methods require that all parts are cut in same direction. With the new option, the cutting direction for all parts is aligned right away, instead of having to manually change each item’s direction.

Visualizing option – it is now possible to select different lighting options for removal. All the parts in a set can be lit up in the removal area at the same time, thus making set-oriented sorting easier. You can also choose whether or not to print a label. Selecting label templates has been made easier.

Pick and place interface option – to work with several different robot settings, profiles for the robots are created for selection as part of job processing. Thus, it will be easier for the operator to change settings by simply selecting the correct profile.

Time estimation for Gen3 cutters was reworked and allows more options to calculate the production time for fully defined jobs. Cut Editor will show the estimated time for the selected cutter. Third-party software can check time estimations for a specific cutter or every cutter on the shop floor. In Cut Center, the time is visible in the preparation phase and adjusted according to the settings. During production, the remaining time is continuously calculated and shown, giving the operator valuable information about when the next intervention is needed or when the job will be done.

ZCC 4.0

Essential new features in ZCC

Benefit from adjusting cutting parameters on the fly. There’s now no need to abort production and start again with changed settings. ZCC allows you to pause production, modify the desired parameter (such as depth if, for example, the shape was not cut properly), and resume cutting. Users may even rewind and start production using the desired method again.

The classification of user permissions has been refined. Administrators may grant or deny device operators permission to make specific modifications. Each user must sign in to ensure that they have the necessary and desired permissions. The permissions for users are limited to the basic settings as standard. Configuration during commissioning ensures that all the necessary permissions are granted. With “Remember Me”, the last user remains logged in automatically, meaning they do not need to enter their login details again each time the program starts up.

Thanks to the “Favorite” feature, the lists of materials are clearer, as the filter feature ensures that only the favorites are displayed in Cut Center, making them much easier to find.

You can adjust the feeding speed according to the material, meaning that you are able to define the optimal speed for each material. Alternatively, you may adjust the speed as part of job processing.

Registration with camera depends on the material. For example, reflective or dark materials may need different light settings for the ICC versus light-colored material. Operators can now save the profile for each material and thus reduce the time required for manual intervention.

It is now possible to set material-dependent parameters for the cradle feeder.

The well-known feature for creating fill areas can now be set automatically during the import process. This helps save valuable time when preparing production data.

During batch processing and QR code production, a variety of different jobs can be performed automatically. One new feature is an overall setting for the material or processing method. The material can vary for each job. What is matters is the material in the individual job versus the one selected overall for batch processing. This means that different materials (watch out for the limits) in a single batch can be processed. Batch processing now supports interruption-free processing where material is constantly loaded, thereby resulting in significant time savings.

You can activate or deactivate the vacuum, and it can be adjusted using the integrated control panel in ZCC. Furthermore, the control panel can be used to move to the parking position or initiate feeding. It can also be used for assembling the router bit changer and the tool changer.

ZCC 3.5.0

Essential new features in ZCC

ZCC from Version 3.5.0 runs on Windows 10 and Windows 11.

The interface between Zünd Cut Center and robotic devices for parts removal has been expanded to accommodate UR robots. This opens up additional integration possibilities.

To ensure properly aligned placement in a stack, a direction line has been added for each part. This information is extracted from the source data and informs the robot how to properly align picked parts and neatly stack them.

To further facilitate picking and removing cut parts, it is now possible to project customer-specific data identifying each part.

For creating labels, the user can combine coded information in the QR Code from several data sets so that the code can be used for cutting and also for other purposes such as tracking.

In order to improve the workflow in Zünd Cut Center and implementing it, specific processing methods are available in ZCC.

Notches are essential for properly aligning and sewing together cut parts. Zünd Cut Center can now deduce inward notches from points, circles, or short lines on outside contours.

During the data import, the existing vectors are replaced with notches whose types and sizes are predefined.

ZCC 3.4.2

Essential new features in ZCC

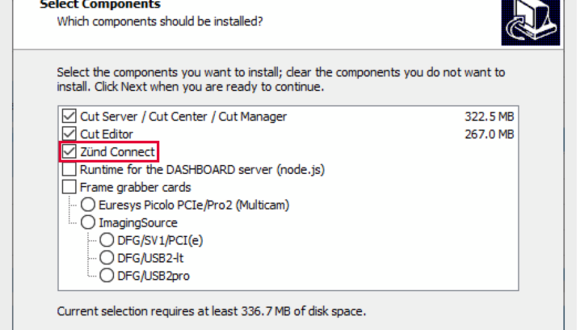

With version 3.4.2 of the Zünd Cut Center – ZCC, Zünd Connect can now also be implemented. Zünd Connect is a monitoring tool. It collects production data from the connected cutters and processes it into useful key figures such as performance, availability and overall equipment effectiveness OEE. For this purpose, productivity is tracked over a freely definable period of time. The Zünd Cut Center – ZCC serves as the data source, if it is connected to Internet. The data upload can be switched off at any time.

ZCC 3.4

Essentials new features in ZCC

A new nesting algorithm improves performance and efficiency compared to the previous version. This update allows customers who have the nesting option to automatically benefit from these improvements.

Bitmaps and logos are now saved directly to the ZCC file. A separate download of images is no longer necessary, making operation even easier.

The new Cradle Feeder 100 now offers an option to automatically perform a cut-off at the end of the job. To do this, ZCC briefly stops advancing the material at the appropriate position and automatically triggers the cut-off function. This allows for roll changes while the cutter is still finishing the current job.