Modular and intelligent kit cutting cell – Zünd at Advanced Engineering 2025

Zünd is set to demonstrate how intelligent modular kit cutting cells are redefining composite manufacturing at Advanced Engineering 2025, taking place 29–30 October at the NEC Birmingham.

As a global leader in digital cutting systems, Zünd will showcase how advanced software, automation and robotics seamlessly integrate to deliver faster, smarter and more efficient kitting workflows across aerospace, automotive, renewable energy and other high-performance industries.

Centrepiece: Fully automated kit cutting cell

At the heart of Zünd’s exhibit is a fully integrated production cell built around a Zünd G3 cutter, featuring both semi- and fully automated workflows. This live demonstration connects data and materials in real-time to maximise cutting throughput, highlighting how intelligent automation enables higher output, optimised material usage, faster processes and the redeployment of labour to higher-value tasks.

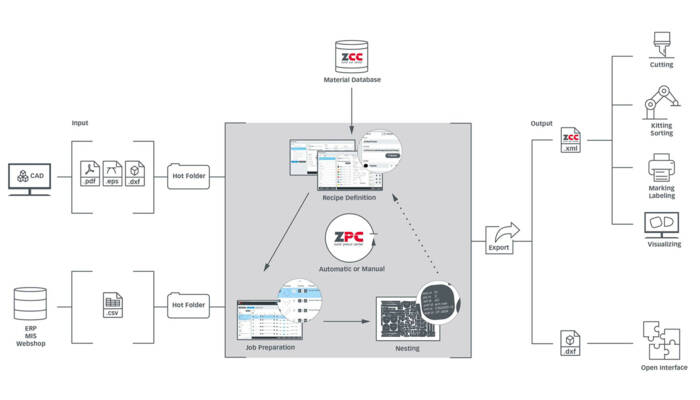

Intelligent digital workflow with Zünd PreCut Center (ZPC)

A key component of the system is the Zünd PreCut Center (ZPC), which drives a complete digital workflow. ZPC provides:

- Intelligent cut file preparation with advanced nesting capabilities to optimise layouts for speed and material efficiency

- Automatic detection of irregular shapes, flaws, or defects in raw materials, ensuring clean, efficient cuts while minimising waste and rework

Data-driven production with Zünd Cut Center Version 4 (ZCC4)

Zünd solutions also enable fully data-driven workflows via Zünd Cut Center Version 4 (ZCC4):

- Accelerates production while maintaining full traceability

- Preserves job metadata, which can be output through a Leibinger inkjet or label printer

- Provides the foundation for streamlined kitting, end-to-end traceability and process control

Enhanced picking and sorting efficiency

Zünd integrates projection-based picking and sorting guidance, visually indicating which parts to remove. This reduces errors, accelerates handling and allows operators to keep pace with the cutter’s productivity.

Full automation with the Robot Table 130

For fully automated workflows, Zünd showcases the Robot Table 130, a collaborative robotic solution that automates material handling:

- Unloads, picks and sorts cut materials alongside the operator

- Reduces repetitive and non-value-adding work

- Lowers production costs while increasing overall efficiency

Integrated approach for large volume production

Whether in fully or semi-automated environments, Zünd’s modular kit cutting cell approach ensures high-volume cutting and kitting with unmatched precision, repeatability and speed, delivering measurable benefits in cost, efficiency, and flexibility across multiple industries.

FibreLINE: Zünd’s largest cutter meets the world’s biggest robot

Another highlight at Advanced Engineering 2025 will be FibreLINE—the integration of Zünd’s largest cutter to date, working in tandem with the world’s largest industrial robot. This groundbreaking high-speed preform system is transforming the production of composite structures across aerospace, automotive, rail, and renewable energy industries.

A recent winner of the prestigious JEC Innovation Award in the Aerospace Process category and shortlisted for the Composite UK Awards for Innovation in Manufacture, FibreLINE leverages Zünd’s Aero Q-Line cutting technology for advanced cutting with fully automated workflows.