Roll-off units

Roll materials require special handling. The Zünd product offering includes roll-off systems that can handle even the most challenging rolled materials.

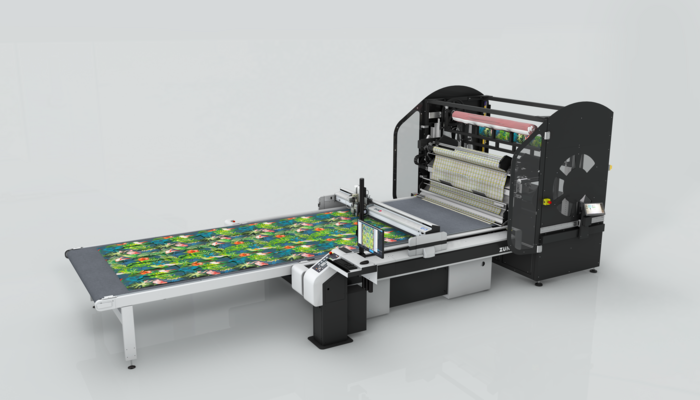

Roll Handling System – RHS6-50

The Roll Handling System – RHS6-50 is a game-changer for automated, uninterrupted single-ply cutting on an industrial scale. The system can handle up to six rolls of fabric which, depending on job requirements, may be identical or of different types. Only the processing method (pattern matching, plain, feature recognition, etc.) must be the same for all rolls. The automated Roll Handling System enables significantly longer periods of uninterrupted cutting, which maximizes the overall productivity of the system.

It autonomously supplies material to the cutter and ensures uninterrupted production even during material changes. It minimizes the need for user interventions and, by extension, staffing requirements.

Scanning the barcode (for roll ID and material length) ensures rolls of material are quickly and easily assigned to the RHS6-50 while they are being loaded onto the carousel. A handy label printer is used to efficiently mark the rolls with an updated barcode as they are removed. The MindCUT Studio Feeder RHS6-50 Add-on allows the RHS6-50 to be seamlessly integrated into the MindCUT software. MindCut also keeps track of material parameters and consumption.

Benefits at a glance

- Material-handling system with integrated, single-ply feeding and autonomous roll changes

- Suitable for tension-free feeding of stretch fabrics

- Integrated edge control for precise material alignment

- Assignment of roll ID and material length via barcode scan

- Label printer for roll ID and residual material length during unloading

- Fully integrated in MindCUT cutter software with MindCUT Studio Feeder RHS6-50 Add-on

- MindCUT software automatically switches to the specified material

- Centralized operation via MindCUT PC or RHS6-50 touchscreen

- Material-consumption data also available through the software interface

Details

- Compatible with G3, S3, and D3 (L-widths)

- Loading capacity: 6 rolls

- Can only be mounted directly to the cutter

- Requires MindCUT Studio with Feeder RHS6-50 Add-on

- Maximum roll weight: 50 kg / 110 lbs per roll

- Maximum roll width: 1,800 mm / 70.8"

- Maximum roll diameter: 400 mm / 15.7"

- RHS6-50 dimensions: 1,710 x 3,300 x 2,570 mm / 67 x 130 x

101" (LxWxH)

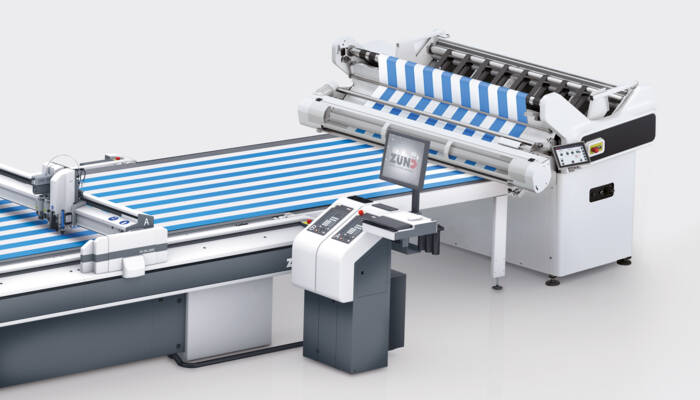

Roll-off unit universal

The Universal roll-off unit is especially suited for light rolls of material that need to be changed often. Changing the rolls is quick and easy. Ideally, the rolled material should be dense and not have a tendency to wrinkle (e.g. paper or vinyl). An adjustable brake effectively prevents the material from continuing to unwind. The use of a material guide roll significantly reduces the potential for wrinkling and creasing.

- Quick, easy roll changes

- Ideal for lighter rolls

- Perfect for paper or plastic films, vinyl

- Suitable for inward/outward wound rolls

- With the addition of a material guide roller, wrinkling is reduced

Details

- Max. roll diameter: 350 mm/13.5 in

- Max. roll weight: 70 kg/155 lbs

- Available for all cutter sizes

Roll-off unit, core support

In contrast to the universal roll-off, the unwind unit with shaft is perfect for textiles and other soft, flexible materials. The roll is secured on a shaft and placed in the roll-off unit. This ensures the material is rolled off smoothly and evenly.

- Ideal for textiles

- Suitable for inward/outward wound rolls

- With the addition of a material guide roller, wrinkling is reduced

Details

- Max. roll diameter: 350 mm/13.5 in

- Max. roll weight: 70 kg/155 lbs

- Roll core diameter: 76 mm/3 in

- Available for all cutter sizes

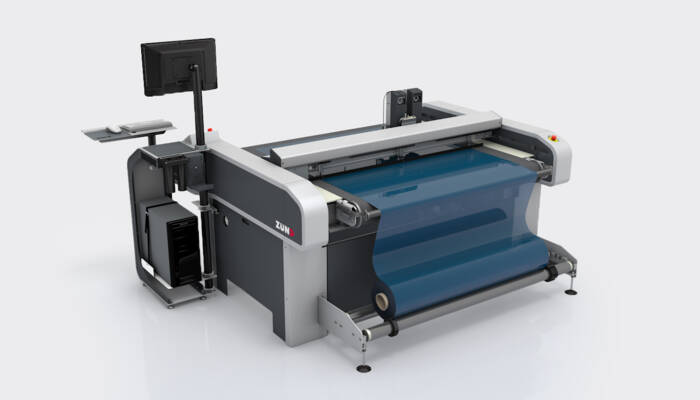

Cradle Feeder

The cradle feeder spreads and feeds stretchy textile materials from rolls precisely and tension free. It can easily handle rolls weighing up to 200 kg/440 lbs. Integrated edge control ensures accurate material feeding even with imperfect roll edges.

The cradle feeder is available in two versions to meet different requirements: Cradle Feeder 100 is suitable for rolls weighing up to 100 kg/220 lbs, while Cradle Feeder 200 can handle rolls weighing up to 200 kg/440 lbs. Both variants have the same functions and advantages, adapted to different weight classes.

- Tension-free feeding of flexible, stretchy textile materials

- Automatic, integrated web-edge control guarantees perfect alignment and feeding accuracy

- Cross-cut feature for manual or automatic cross cuts

- Simple controls with user-friendly touch panel

- Fast, easy roll changes for maximum versatility

- Reliable processing of rolls with defective or missing cores

- Optional roll-off unit with core support/shaft may be installed

- Fully supported by Zünd Cut Center – ZCC and MindCut software

Details

- Available for rolls up to 100 kg/220 lbs (model 100) and 200 kg/440 lbs (model 200)

- Roll diameter: max. 400 mm/15.75 in

- The use of the cross-cut feature requires a cutter extension

- Suitable for both inward and outward-wound rolls

- Optional guide rails (length 3 m) make it easy to push the cradle feeder out of the way when not in use

- Compatible with G3, S3, D3 (available in L, XL and 3XL widths)

Roll-off unit, shaft, active

The active roll-off unit with shaft is equipped with a motor. The roll-off unit with shaft offers the additional capability of rewinding the material at the end of the material advance. This effectively prevents creasing as the material is fed onto the working area.

- Ideal for textiles

- Material that continues rolling off is rewound with a motor-driven rewind

- Suitable for inward/outward wound rolls

- With the addition of a material guide roller, wrinkling is reduced

Details

- Max. roll diameter: 350 mm/13.5 in

- Max. roll weight: 70 kg/155 lbs

- Roll core diameter: 76 mm/3 in

- Available for all cutter sizes

Material guide roll

The material guide roll effectively prevents creasing of textile materials. In the process, the material is fed over a guide roll to spread it. We recommend always using the material guide roll in combination with a roll-off unit!

- Optimized material guidance and reduced friction minimize wrinkling

- Ideal for stretch fabrics and rougher rolled materials

Roll-up unit shaft, active

The motor-driven roll-up unit with shaft is used for continuous, automatic production of large kiss-cut orders. The material is immediately rolled onto the core after processing, which ensures that it remains clean and free of kinks and creases. This roll-up unit is ideally suited for vinyl, film, or printed fabrics with a max. roll weight of up to 70 kg/155 lbs.

Roll-up unit tray, active

The motorized roll-up tray is suitable for small kiss-cut jobs. The vinyl is automatically rolled up in a tray after processing. After each cut-off, the coreless rolls can be removed from the tray immediately without interrupting production. Suitable for vinyl sections no longer than 20 m/65 ft.

Collection tray

The collection tray is useful for collecting cut parts and waste. It ensures a clean working environment. For emptying, the tray can be removed from the cutter in a few simple steps.

- Collects cut parts and waste

- Emptying occurs without interrupting production

Downloads

Product information and brochures