Order at last

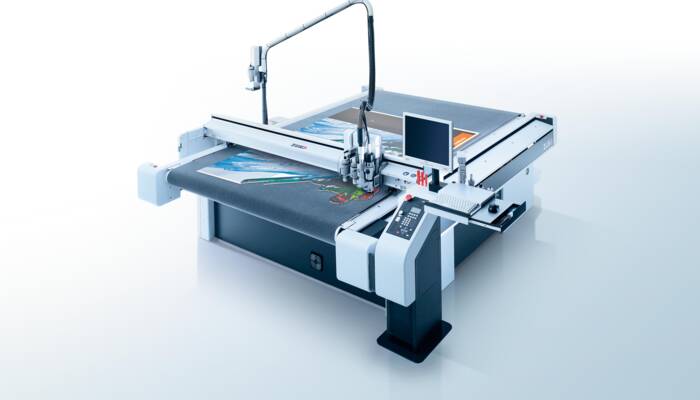

Automation in printing and advertising technology is the trend. Digital printing, in particular, demands automation. The challenge here is to integrate downstream processing and finishing steps. Otherwise, a lot of things go up in smoke. (From "display," August/September 2020 edition)

The cutter specialist Zünd Systemtechnik is convinced that automation brings advantages when it is done correctly, i.e. intelligently. "To automate intelligently means to think carefully about which processes are worth automating and which are not. This is a process of weighing up the pros and cons, because not every effort for automation is in the right proportion to the profit. Intelligence also means that automation does not necessarily have to be expensive. Often even small steps have a big impact on efficiency. A specific example of this is nesting," says Lars Bendixen, segment manager for advertising technology at Zünd.

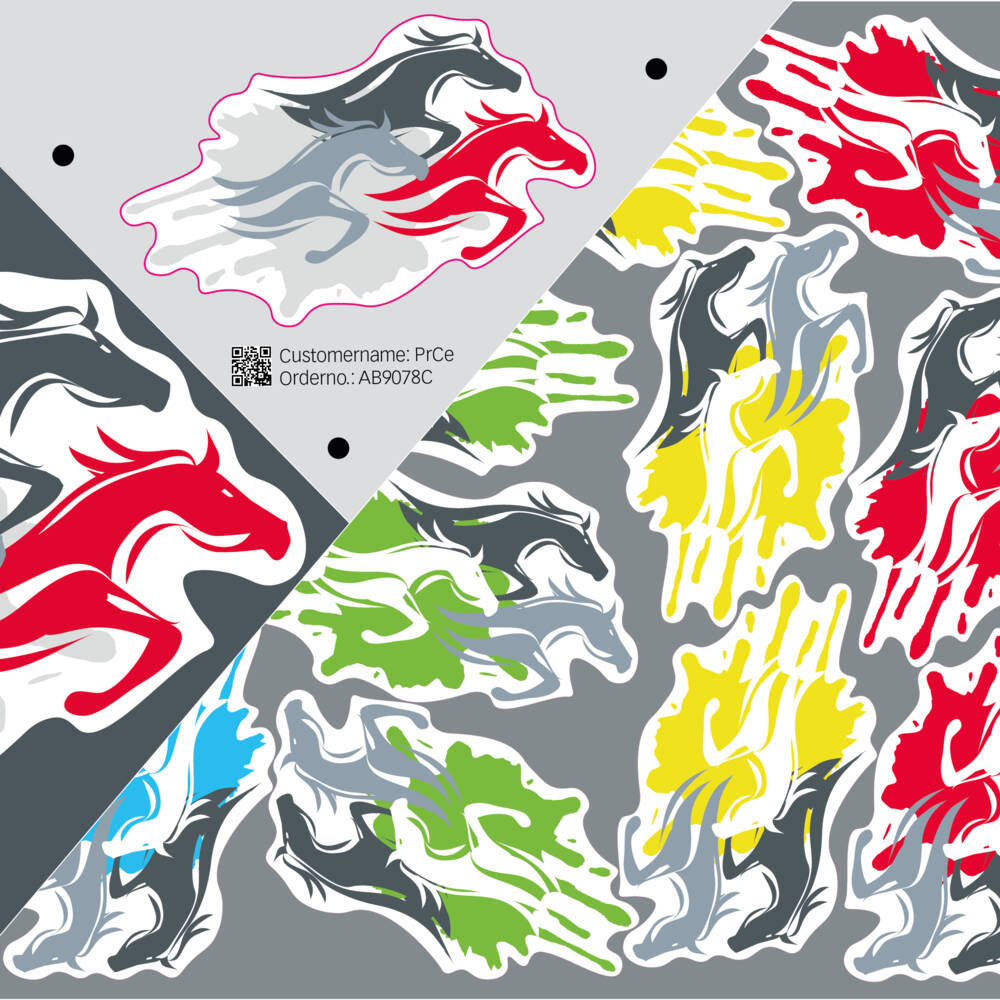

No matter whether you are dealing with a single item, small, partial or large series, if you have productivity and profitability in mind, nesting processes can help you achieve optimum utilization with several jobs on one sheet or plate (paper, cardboard, plastic or wood) or on films and textiles from a roll. It is usually complicated when the cut parts have to be assigned to the respective order again after cutting. To solve this problem, Zünd has developed the new PrimeCenter pre-press software together with the French software company Caldera.

Disconnect and reconnect

As Bendixen explains, PrimeCenter serves as the control center for the creation of print and cut data. PrimeCenter simplifies data preparation and output and enables users to automate their data workflow between design, print and cutting individually and according to their needs. "Based on the available PDF print data, PrimeCenter sorts the various jobs on a sheet or roll material - depending on the desired characteristics of maximum material utilization, delivery deadline or other. This nested print image can be fed into the production process. PrimeCenter then passes on the metadata associated with each order throughout all production steps. At the end of the production line, after cutting, a robot gripper arm in the fully automated version can then remove the individual parts and assign them to the respective orders. PrimeCenter provides the necessary metadata at the end of the production line."

Meta data always available

"This is revolutionary for our customers with large-format printing applications," Bendixen says. "Everyone who produces digitally has to sort different jobs on one sheet again and again. In production, however, the metadata is usually lost. This means information like the order number, customer name, number of parts per set, quantity of sets, right or left parts, etc. All this information is not stored in the print PDF and is therefore not passed on in the course of further processing. PrimeCenter is the first software to do so." According to Bendixen, PrimeCenter is compatible with any RIP software.

Now it is of course the case that a great deal of manual work is still being done, especially in the advertising technology segment. The need for manual work or automation can also vary greatly depending on the season. Zünd and Caldera have taken this fact into account in the development of PrimeCenter. Therefore, Bendixen says, users are offered as much flexibility as possible: "Regardless of whether the user makes the settings manually or wants to automate them completely, PrimeCenter offers users the maximum freedom to automate their pre-press workflow in the way that makes sense for them.

With full automation, the metadata is exported from an MIS, an ERP or a web shop via hot folders, customized file names or with XML-based job tickets. With the different program versions Basic, Pro and Max, the degree of automation can be adjusted at any time

"The unique thing about PrimeCenter," says Bendixen convinced, "is that the individual parts can be reassigned to the orders after cutting or sorted according to other characteristics, such as individual dispatch or collective delivery. No matter whether it is a single item, a small order, a partial or large print run. It's never been seen before in the large format segment."