Velocity Composites revolutionise composite manufacturing

Reducing operating costs and all forms of waste through innovative manufacturing processes is the aim of Velocity Composites. In return this helps the company meet their customers global challenges of new aircraft programs, increased aircraft production rates, and cost challenges associated with aircraft. To achieve this goal, they have been supported by latest digital cutting technology from Zünd.

Formed in 2007, Velocity Composites manufacture advanced carbon fibre and process material kits for use in the production of aircraft. The Burnley headquartered company, with a second site in Fareham, uses its process knowledge, industry accreditations, and proprietary technology to reduce the amount of material and process waste created in the manufacture of advanced composite aerostructures. In turn, this reduces the aircraft manufacturers’ costs to allow its customers to meet the cost challenges and rate demand from the global OEMs: Airbus and Boeing. The company is listed on the AIM (Alternative Investment Market), the growth market of the London Stock Exchange, in 2017.

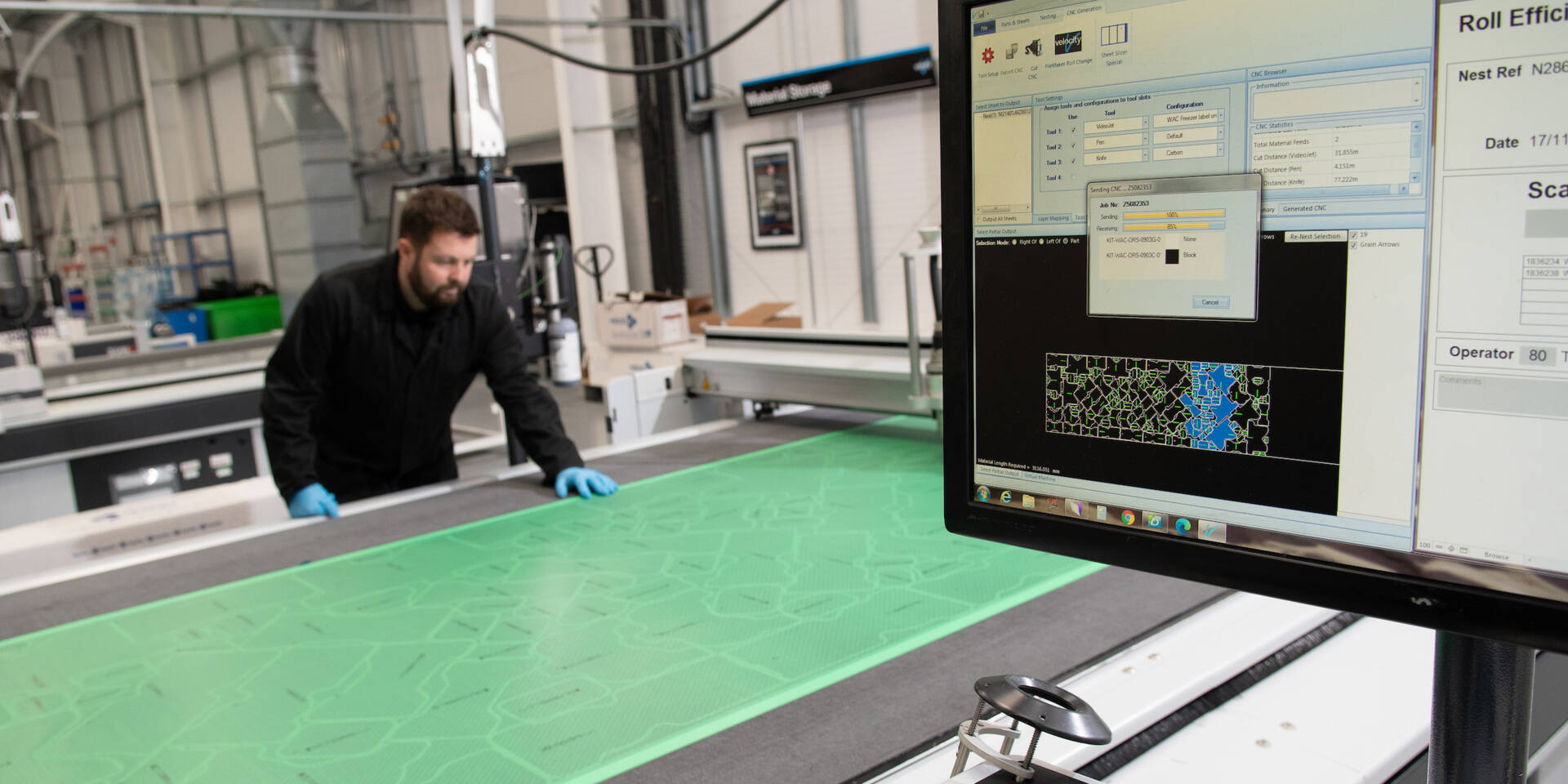

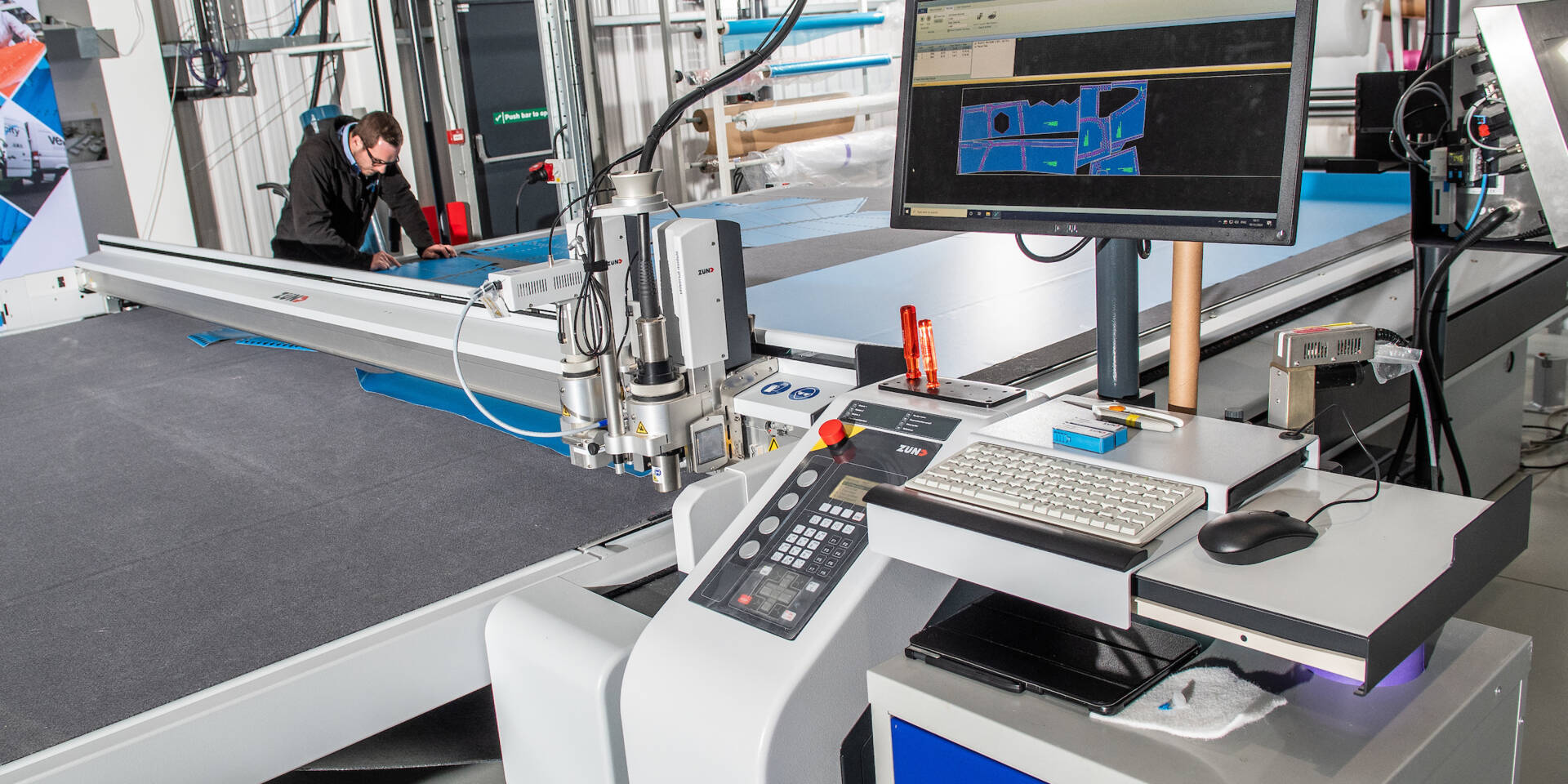

The majority of the raw materials used by Velocity are supplied on rolls and are both expensive and temperature-sensitive with long lead times from single source providers. Having used equipment from other suppliers Velocity Composites purchased their first Zund cutter in 2011 for their aerospace composites kit manufacturing department. Today, the company has a total of twelve Zund G3 digital cutters across their Burnley and Fareham state-of-the-art production sites. Jon Bridges, Chief Executive Officer of Velocity Composites said “We first spoke to Zund ten years ago and we were very impressed with the flexibility and endless digital opportunities the cutter offered. As a high-end service provider in a very regulated industry, business, flexibility is very important to us because we don’t just cut a limited number of known products. Our customers expect us to be flexible and process various composite materials, depending on the parts being manufactured and the end-use”. Jon added- “The Zund G3 proved to be very adaptable, and the versatile tools could process various materials with ease. We were also impressed with Zund’s approach to software flexibility as we have developed our own system to drive the machines, manage material efficiency and control the technical requirements of our products. This was an important factor to us as the digital machines allowed for our manufacturing cells to talk to our VRP system in real-time and confirm process adherence, traceability and control ”.

Due to the size of Velocity’s global customer and supplier base, the company has always worked towards being the advanced technology centre of excellence for material management and manufacturing. They have heavily invested in IoT and have built proprietary software for the purpose of connecting and exchanging data with their Zund cutters and other systems over the internet. Jon Bridges said “Real-time data is always more valuable than seeing data from past events. We need real-time awareness of how much material we are using, any material defects we have had to work around, material batch traceability, how often the cutters are stopped (including cause) and their production start time and end time. This information is fed through to our live dashboard system which is reviewed by production managers in real-time. We also want to take an Industry 4.0 approach using our data and reduce manual steps in our workflow, integrate with all other parts of our system, and automate processes where possible, including material stock control, freezer movements, and job planning. The Zund cutter is a very important junction to our manufacturing process as it both receives and creates valuable process data which we can use to control, report, and improve”.

The company also holds stock of Zund critical parts at their sites to ensure production never halts and customer orders are always delivered on time. Jon Bridges said “Strategic supply chain alliances are very important to us as we look to integrate existing technology into our business. Our relationship with Zund has always been evolving and their approach to this was one of the many reasons why we chose their solution above others. They have always supported our customer first and digital manufacturing approach and enabled us to develop our capability to deliver growth.”

In line with the global nature of its business Velocity Composites are entering the North American market equipped with two Zund G3 Digital Cutters. The subsidiary in the USA is looking to expand the company’s manufacturing excellence by creating advanced “flexible” manufacturing sites equipped with Zund digital cutters. These highly adaptable sites can easily and quickly be constructed, in a matter of weeks to be based close to or on-site with customers. This scalable model has global reach and potential that Velocity Composites has identified as key to rolling out its technology and services alongside customers.