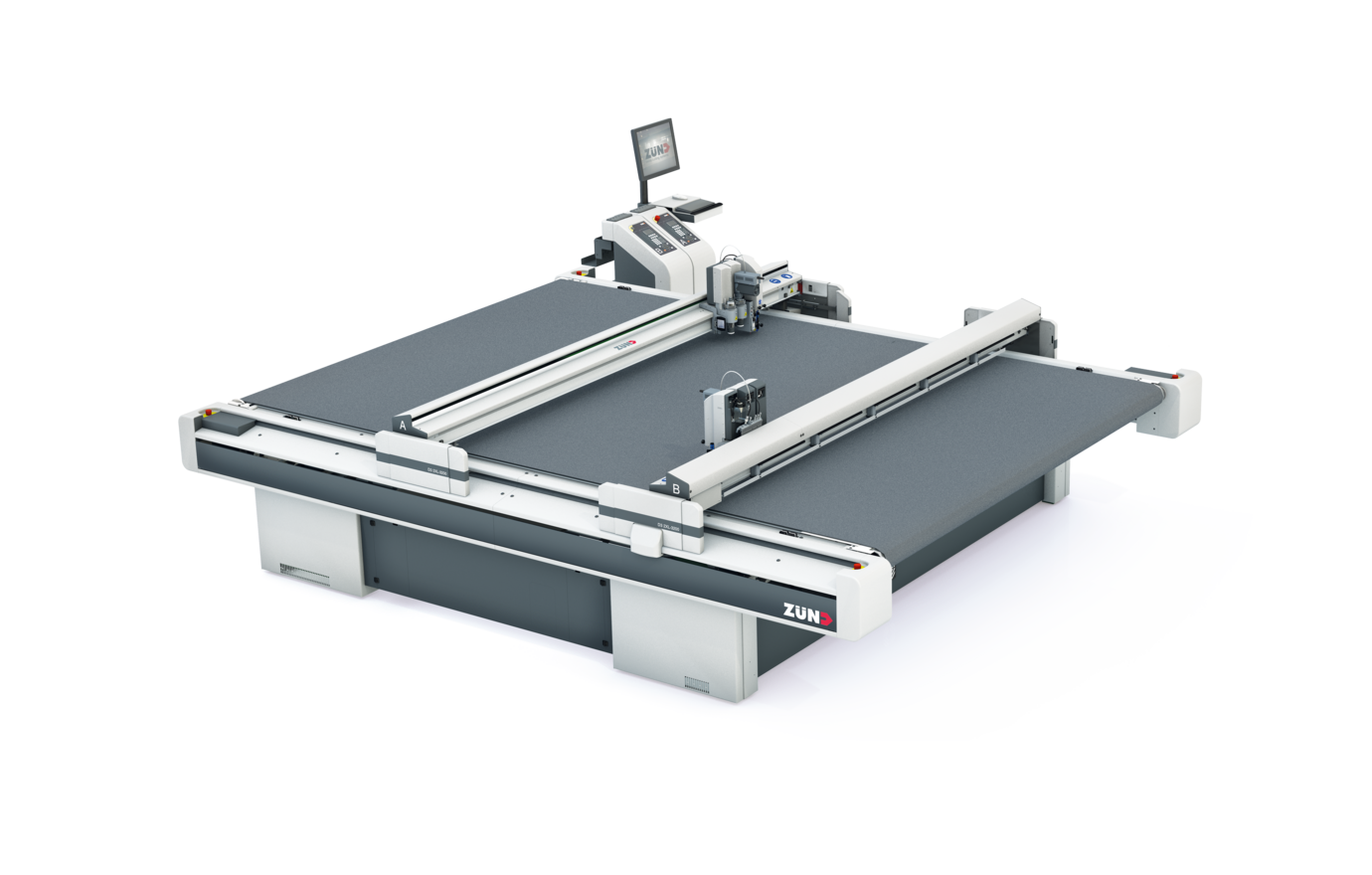

D3 Digital CNC Cutter

Double your productivity: The dual-beam system of the D3 digital cutter sets new standards in performance.

Two beams, twice the performance

With its innovative dual-beam system, the D3 sets new standards in performance. The two beams can each be equipped with up to three different modules, instantly doubling the throughput. The cutter controller optimally allocates the jobs to each of the two beams, ensuring maximum productivity.

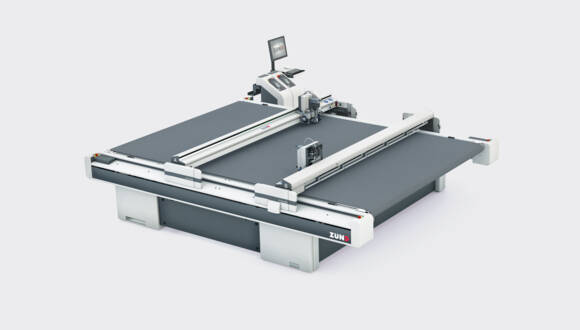

D3 Cutter Overview

The 4 different cutter models of the D3 line let you select the perfect machine size for all your applications. Our digital cutting systems are intelligent, efficient, and ready for the future.

Two beams for maximum productivity: The D3 sets new performance standards with its innovative dual-beam system. The two beams can each be equipped with up to three different modules, potentially doubling the throughput in one fell swoop. The intelligent cutter controller optimally allocates the jobs to each of the two beams, ensuring top productivity. With its powerful, rugged design, the D3 lives up to its true potential in industrial environments.

The D3 is a precision machine. From innovative drive system to blade, all components are perfectly coordinated. Produce your jobs at the highest quality level, economically and efficiently. Your customers will be impressed with the results.

The price-performance ratio of the D3 series is excellent. We use only the most modern technologies and top-quality components. The flexibility, reliability, and quality of the digital cutter cannot be matched by any competitor.

The extraordinary modularity of our cutting solutions is truly unique. You can always make your D3 adapt to new requirements with modifications and upgrades. Define which functions your cutting solution has to perform and make your cutting system adapt to new requirements with modifications and upgrades. Zünd’s tried and tested modular tool system is available on both beams of the D3.

D3 Cutter Sizes

Choose from 4 different sizes to select the perfect machine for your application.

Zünd D3 – powerful, innovative, flexible

The D3 gives print service providers the ability to dramatically increase productivity in their finishing departments. As is standard with Zünd solutions, the cutting system integrates seamlessly in existing production environments and brings with it a clear competitive advantage in markets that demand the ultimate in performance.

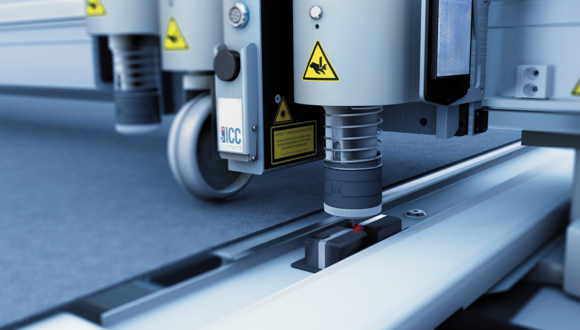

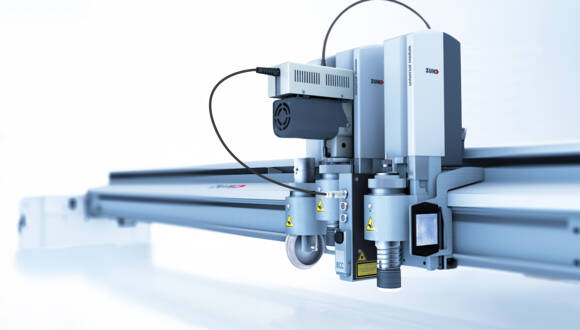

The setup for knife-cutting, routing, and creasing tools is fully automated because of the integrated tool initialization system. The ITI system is fast and precise and helps the cutter determine the correct processing depth for each tool very efficiently.

You have the flexibility to precisely choose the tools you need for the job at hand. Combine the required tools based on your specific production requirements, and keep in mind that you can equip each beam with up to three different tools.

The D3 combined with Zünd Cut Center create a complete cutting solution that offers the ultimate in performance and productivity. This includes superb accuracy throughout the entire production process. The precision of the system’s direct-drive, combined with state-of-the-art software and controllers, guarantee maximum throughput and productivity.

The ergonomic design of the cutter makes the operator's job easy and creates even greater efficiency. The D3 can be automated according to specific needs, with cutter extensions and various material handling systems. These automation features enhance the production workflow and ensure superior productivity.

The Zünd D3 cutter in action

Reliable and productive – high-performance modules for every application

Find the perfect module & tool for every application.

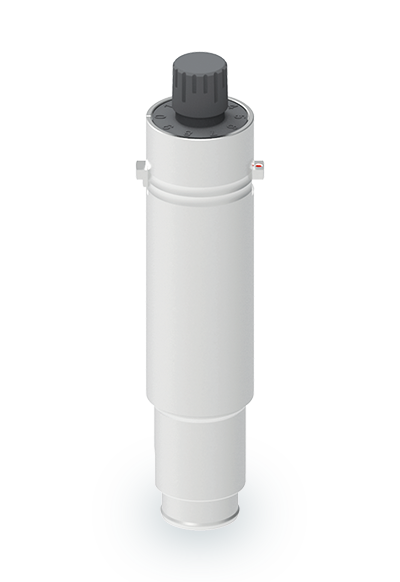

The CTT1 is perfect for processing single-wall corrugated boards.

The CTT1 is perfect for processing single-wall corrugated board. The tool accommodates crease wheels with a diameter of 61 mm/2.4 in and a width of 20 mm/.8 in. Fully supported by the cutter software, the tool produces high-quality creases both with and against the corrugation without tearing or cracking the top sheet. The crease wheels simply snap into the holder, making them very easy to insert and replace.

- Clean creases without tearing

- Directional pressure adjustments

- Crease wheel diameter: 61 mm / 2.4 in

- Crease wheel width: 20 mm/.8 in

- Crease wheels snap into holder

- Compatible with G3, S3, D3

Materials

Universal creasing tool for folding carton, polypropylene, twin wall, etc.

Universal creasing tool for solid cardboard, PP, or corrugated boards. For crease wheels with diameters of up to 24 mm/0.94 in.

- Clean creases without tearing

- Directional pressure adjustments

- Compatible with G3, S3, D3

Materials

Creasing of double- and triple-wall corrugated board.

The CTT3 is designed for creasing double- and triple-wall corrugated board. Accommodates crease wheels with a diameter of 90 mm/3.5 in and a width of 28 mm/1.1 in. The tool produces high-quality creases both with and against the corrugation without tearing or cracking the top sheet. The crease wheels simply snap into the holder, making them very easy to insert and replace.

- Clean creases without tearing

- Directional pressure adjustments

- Crease wheel diameter: 90 mm / 3.5 in

- Crease wheel width: 20 mm/.8 in

- Crease wheels snap into holder

- Compatible with G3, D3

Materials

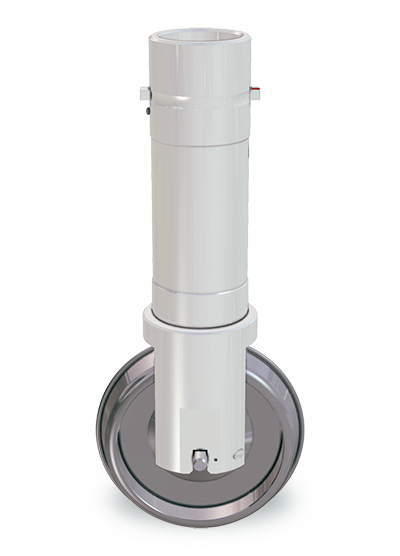

Suitable for fabric and technical textiles. The driven rotary blade allows for very high processing speeds.

The Driven Rotary Tool is designed for cutting all manner of textiles reliably and economically. The material is cut with a motor-driven ten-segmented blade. The blade geometry reduces the drag force on the material considerably and also helps cleanly sever thread or fiber. This processing method produces clean, precise cuts even on very loose, coarsely knit materials.

Choice of two RPM setting depending on the application. Also suitable for cutting materials with low melting points.

- Use of rotary blades reduces drag on the material

- Choice of 2 RPM settings (20,000/12,000 rpm)

- Clean separation of each thread or fiber

- Compatible with G3, S3, D3, L3

Materials

D3 Modular material-handling solutions

Downloads

Questions?

Contact us for more information, for scheduling a demonstration, and for anything else you might like to know about digital cutting.