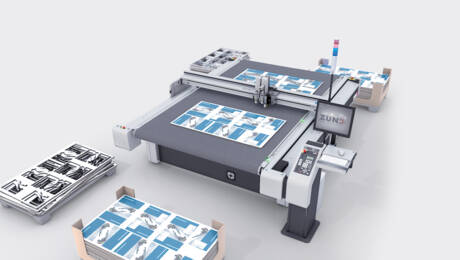

G3 Digital CNC Cutter

Uncompromised performance and precision: The G3 digital cutting system is based on the most flexible, adaptable, and easily expandable machine concept on the market.

Modular design for maximum flexibility

The extraordinary modularity of our cutting solutions is truly unique. You can always make your Zünd G3 system adapt to new requirements with modifications and upgrades. Zünd’s modular design concept lets you put together a tailor-made cutting solution configured to meet specific production needs. Zünd cutters are a safe investment and offer maximum value retention.

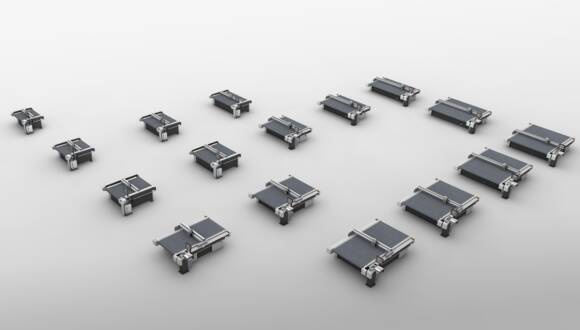

G3 cutter overview

The 11 different cutter sizes of the G3 line let you select the perfect machine size for all your production needs – no matter the area of application, product, or whether you produce small runs, large runs, or prototypes. Our digital cutting systems are intelligent, efficient, and ready for the future.

The G3 construction and design are tailored to the needs of our customers. Simple, user-friendly and ergonomic operations are the result. The intelligent safety features of the G3 actively support the operator and interfere only when absolutely necessary.

Zünd’s distinctive modular design is truly unique and allows you to configure the required tooling in a few quick, easy steps. The resulting flexibility lets you react instantaneously with modifications and upgrades to changes in production requirements, saving you both time and money. The G3 cutting system is a safe investment and offers maximum value retention.

The G3 flatbed cutter is a precision machine. With innovative technology behind everything from drive systems to blades, all components are perfectly coordinated. Produce your jobs at the highest quality level, economically and efficiently. Your customers will be thrilled with the results.

The overall productivity of the G3 cutting system is unrivaled. We achieve this through the use of intelligent control technology, robust machine components, and sophisticated cutting technology. All components are perfectly coordinated.

The price-performance ratio of the G3 cutter series is outstanding. We use only the most modern technologies and highest-quality components. The flexibility, reliability, and quality of the G3 cutter cannot be matched by any competitor in the industry.

G3 cutter sizes

Choose from 11 different sizes to select the perfect machine for your application.

Zünd G3 – perfection is in the details

Zünd cutters are high-precision machines. All components – from drive system to cutting blade – are designed and manufactured to work together perfectly. This lets you produce efficiently and wow your customers with perfect results.

Define which functions your G3 cutter has to perform and configure your modular Zünd tooling accordingly.

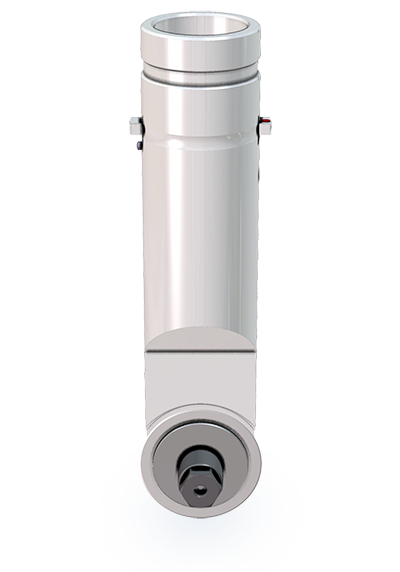

Quick, precise, time-saving: The setup for knives, router bits, and creasing wheels occurs through a fully automatic initialization system. Manual adjustments for determining proper cutting depths are no longer necessary. The ITI Initialization System makes the process quick and precise.

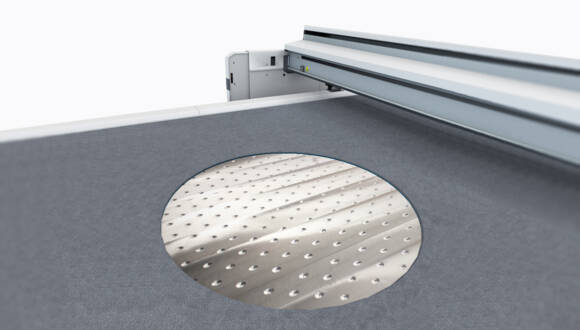

Energy-efficient vacuum turbines ensure reliable material hold-down during the cutting process. The vacuum area is divided into zones, which can be switched on and off individually across the width of the machine.

On a G3 cutting system, you can process materials up to a thickness of 110 mm/4.3 in. Depending on your requirements, the G3 can be configured with a beam height of 60 or 120 mm/1, 2 or 4 in. This means more flexibility and versatility in your production workflow.

The automatic router bit/tool changer ARC dramatically reduces set-up times and simplifies tool handling. The magazine can accommodate up to eight different cutting, polishing, or engraving bits. The bits needed for processing are automatically removed, clamped, initialized, and cleaned after each use. The ITI initialization system checks the zero point after each tool change, ensuring perfectly consistent routing depths.

Modular, flexible, and adaptable high-performance modules

The right modules & tools for every application.

Low-maintenance tool for single-ply cutting of glass and carbon fiber as well as technical textiles.

Non-motor-driven tool for using Zünd HSS rotary blades (ø 28 mm/1.1 in) on a PU cutting underlay. The Wheel Knife Tool is an efficient, cost-effective tool option for single-ply cutting of glass and carbon fiber as well as technical textiles. The use of HSS steel blades in this tool allows for very high processing speeds and a clean, efficient cutting process.

Cutting is done in pressure mode. The pressure settings can be adjusted to precisely match the material properties and desired cut quality. A special PU (polyurethane) underlay is used in conjunction with this tool to prevent damaging the cutting surface.

- High cutting speeds

- Uses rotary, high-speed steel blades (HSS)

- Processing is possible without vacuum hold-down

- Clean, efficient cutting process

- Special polyurethane cutting underlay

- Compatible with G3, D3

Materials

Tool with nine different cutting angles. Perfect for 3D designs made of polyester fiberboards and acoustic panels.

The V-Cutting Tool is the perfect tool for producing complex, three-dimensional structural designs made of cardboard, foam-core materials, or corrugated/honeycomb display boards. A well-thought-out design allows for quick tool changes and easy, precise angle adjustments. Suitable for material thicknesses of 16–25 mm /0.63–0.98 in.

The VCT2 can cut at nine different angles (0°, 5°, 10°, 15°, 22.5°, 30°, 45°, 50°, 60°).

- Simple, precise angle adjustments

- Produces cuts at nine different angles

- Very quick blade changes

- Compatible with G3, D3

Materials

Polyester fiber boards

Acoustic panels

Perfect for producing complex, 3D structural designs made of twin-wall sheets, cardboard, or foam.

The V-Cutting Tool is the perfect tool for producing complex, three-dimensional structural designs made of cardboard, foam-core materials, or corrugated/honeycomb display board. A well-thought-out design allows for quick tool changes and easy, precise angle adjustments. Suitable for material thicknesses up to 16 mm / 0.63 in.

The VCT1 can cut at eight different angles (0°, 5°, 7.5°, 10°, 15°, 22.5°, 30°, 45°).

- Simple, precise angle adjustments

- Produces cuts at eight different angles

- Very quick blade changes

- Compatible with G3, S3, D3

Materials

and much more

Cost-effective routing and engraving tool.

At the heart of the URT is a 300 W router spindle which operates at up to 80,000 rpm, depending on material and application. The URT is the perfect tool for easy routing jobs and for engraving a wide range of materials.

The URT can easily be converted from a router to an engraving tool. In engraving mode, the height of the tool can be precisely adjusted with a micrometer screw. This ensures precision engraving, with consistent line widths and depths.

The airflow from the well-designed dust-extraction system effectively cools both the router bit and spindle, which significantly increases their longevity.

- Routing and engraving with one tool

- Consistent, precise control of routing depth

- 300 Watt router bit spindle with up to 80,000 rpm

- Stepless adjustable speed

- Wide assortment of Zünd router bits available

- Compatible with G3, S3, L3, D3

Materials

G3 Modular material-handling solutions

Downloads

Questions?

Contact us for more information, for scheduling a demonstration, and for anything else you might like to know about digital cutting.

Convincing arguments

for Zünd

Fabric or acrylic, cutting, creasing, or perforating - our cutting systems impress with their flexibility. The wide range of materials and processing methods make the cutting solutions almost universally applicable. It helps you better cope with increasing numbers of short runs and customer demand for customization and personalization.

With Zünd you are making a safe investment. You can easily and cost-effectively retrofit a Zünd cutter at any time. Configure your digital cutting system according to your specific production needs. We will gladly help you assess your current and future requirements and advise you on a configuration that is tailor-made for you.

Digital cutting increases your productivity in many ways. Reduce set-up times, optimize repeatability, increase cut quality, no matter whether you are producing one-offs or high-volume jobs. Digital cutting allows you to expand and differentiate your product offering at any time. You become more flexible in order planning and processing and can make changes quickly, economically, and on the fly. Zünd cutters are easy to integrate into your digital workflow. Converting to digital cutting creates transparency. It provides relevant data on performance and productivity so you can make the right decisions.

New applications, new materials, new services - a wide selection of tools and functionalities give you more latitude. You can offer an even broader spectrum of choices and solutions to meet your customers' needs. Even some that you may not currently have on your radar.

Zünd cutting solutions are precision equipment. All components - from the drive system to blade - are coordinated in every aspect. Zünd cutters offer exceptionally high precision and repeatability.

Their open architecture makes Zünd cutting systems easy to integrate in a wide variety of production workflows and software environments. You decide for yourself what your workflow should look like.

Time is money - software should be well designed and easy to learn. Zünd software delivers on all fronts. It is intuitive, interactive, and supports the user throughout the entire production process.

Process automation is the path to efficient and economical digital cutting. Zünd offers the right automation solutions for every step of the workflow - from material transport and tool handling to registration and material capture and the removal of cut parts.

Innovative technology, robust construction, and minimal downtime guarantee low maintenance costs and high reliability. Zünd cutters are a safe investment and offer low cost of ownership and maximum value retention.

Swiss quality in design and build – this means above all that we rely on solid engineering driven by innovation. This results in highly robust and extremely durable cutters. Reliability extends to all aspects of a Zünd cutting system, including the tools that come with it. They, too, are developed by Zünd and are just as robust. We put them through the same rigorous quality and performance assessments before adding them to our lineup. This gives you the assurance that the tools and the cutter are a perfect match.

Since its foundation in 1984, Zünd has accumulated a tremendous amount of experience in digital cutting. All this expertise in digital cutting technologies and many different applications is the perfect foundation for developing cutting solutions that will help you gain a competitive advantage. We know the challenges you are facing.